Quality Control Laboratory

Our Quality Control Laboratory, staffed with expert personnel, conducts comprehensive inspections throughout the entire process from raw material intake to final product output. This ensures the production of high-quality goods. Consequently, by minimizing error margins, we elevate customer satisfaction to the highest levels.

Precision measurements are conducted using 3D measuring devices (Faro) and the PolyWorks software. This combination ensures highly accurate measurement results.

The mechanical properties of materials are determined using the Tensile Break Test Device, facilitating accurate identification of their strength and durability characteristics.

Cutting Device

Mounting Press

Polishing Device

In metallography, materials are cut to appropriate sizes, subjected to sanding and polishing processes, and prepared for subsequent testing. This ensures they are suitably ready for various tests.

Microscopes are utilized for analyzing and identifying the internal structure of materials, providing essential insights into their composition and properties.

The stereo microscope is an optical tool that enables the examination of metals too small to be seen with the naked eye. It is particularly utilized in measuring the depth of weld penetration or in conducting distance measurements.

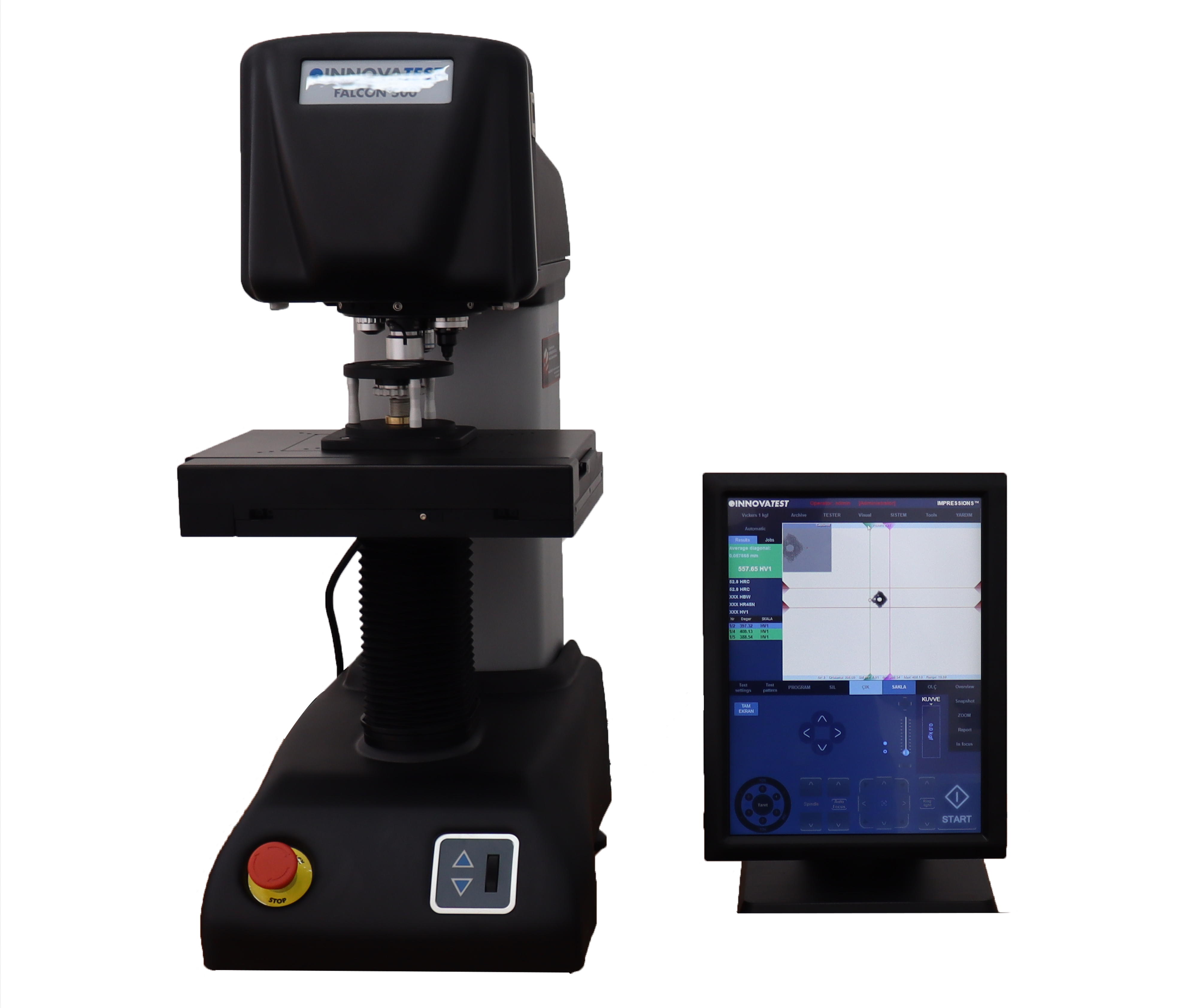

The Hardness Measurement Device is used for measuring the hardness and case-hardening depth of materials.

The Spectrometer Device is employed for the analysis of the chemical composition of materials.

Liquid Penetrant Testing is applied to detect invisible cracks in cast parts or welds, identifying flaws that are not apparent to the naked eye.

These devices are used to determine the compliance of painted or coated materials with specified standards.